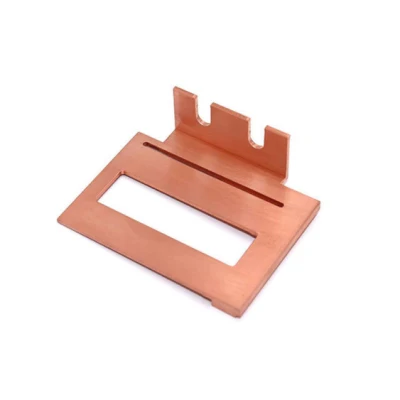

Factory Price Customized Cast Iron Electric Power Accessories

Description

Basic Info

| Model NO. | GL1953 |

| Casting Method | Metal Casting |

| Casting Form Material | Metal |

| Casting Metal | Cast Iron |

| Casting Form Usage Count | Permanent |

| Surface Treatment | Sand/Die/Investment Casting |

| Surface Roughness | According to The Customer |

| Machining Tolerance | +/-0.01mm |

| Standard | GB |

| Certification | CE, RoHS, ISO 9001:2000, ISO 9001:2008 |

| Lead Time | 15-25days |

| Molding | According Drawings |

| Applications | Auto/Motorcycle/Agricultural/Ship/Railway/Hardware |

| Transport Package | in Pallet or as Your Requrement |

| Specification | Customize |

| Trademark | Great Lion |

| Origin | Hebei, China |

| HS Code | 732510100 |

| Production Capacity | 2000ton Per Month |

Product Description

Factory Price Customized Cast Iron Electric Power AccessoriesProducts Decription

Mold Material | SKD61, H13 |

Cavity | Single or multiple |

Mold Life Time | 50K times |

Product Material | 1) ADC10, ADC12, A360, A380, A413, A356, LM20, LM242) Zinc alloy 3#, 5#, 8# |

Surface Treatment | 1) Polish, powder coating, lacquer coating, e-coating, sand blast, shot blast, anodine2) Polish + zinc plating/chrome plating/pearl chrome plating/nickel plating/copper plating |

Size | 1) According to customers' drawings2) According to customers' samples |

Drawing Format | step, dwg, igs, pdf |

Certificates | ISO 9001:2015 & IATF 16949 |

Payment Term | T/T, L/C, Trade Assurance |

. Product categories include CNC Machining Parts, Sheet Metal Stamping Parts, Casting Parts, Plastic Injection Molding Parts, Molds, etc. With excellent ISO 9001 quality control system, our products have been provided to North America, South America, Europe, Oceania, East Asia, Middle East, South Asia etc. We will consistently insist principle of to cooperate with our customers.Custom Parts Total Solution

| Service | · CNC Machining (Turning, Milling, Grinding, Drilling, Wire EDM) · Sheet Metal Fabrication & Stamping( Laser cut, CNC bend, CNC punch, Riveting, Welding) · Casting (Die Cast, Sand Cast, Gravity Cast, Investment Cast) · Plastic Injection Molding & rubber molding · Moulds |

| Materials | Aluminum, Zinc/Zamak, Magnesium, Brass Iron, Mild Steel, Carbon steel, Alloy steel, Stainless steel, Copper Titanium Plastic: PE PP PS ABS PC PA(Nylon) POM PVC PBT PMMA TPU TPE etc Rubber |

| Surface Treatment | Shot peening, Sand blasting/ Bead blasting, Polishing, Brushing Passivation, Powder Coated, Painting, E-Coating/Electrophoresis Electro zinc plating, Nickel plating, Chrome plating, Silver plating, Gold plating PVD coating Laser etching, Silk Screening |

| Drawing Format | Stp, Step, Igs, X_T, AutoCAD(DXF, DWG), PDF, JPG etc |

| Quality Assurance | Raw mateiral inspection, Full inspection during manufacturing, Random inspection during production, Final production before shipping. |

Our Contact