High Reliablity High Tg Printed Circuit Boards for Industry Control

Description

Basic Info

| Model NO. | PCB-2 |

| Insulation Materials | Epoxy Resin |

| Brand | Hl-PCB |

| Surface Treatment | Immersion Gold |

| Mini Hole Diameter | 0.2mm |

| Borad Thickness | 1.6mm |

| Count Layer | 8 |

| Inner/Outer Copper Thickness | 1oz/1oz |

| Min Trace Width/Spacing | 4mil/4mil |

| Certificated | ISO9001, ISO14001, CQC, IATF16949, UL, RoHS etc. |

| Transport Package | Vacuum Packing/Blister/Plastic /Carton |

| Trademark | HonLynn Circuit |

| Origin | Shenzhen, Guangdong |

| HS Code | 853400 |

| Production Capacity | 120, 000 |

Product Description

High Reliablity high Tg Printed circuit boards Manufacturer for Industry control

Shenzhen Honlynn circuit. is a High-level standard PCB customized manufacturing, a National High tech professional precise new enterprice. We certificated UL, ISO9001, ISO14001, ISO / TS16949, CQC and a series of qualification.With over 10+ years experience of producing high-level standerd PCB, and our expertise team, we keep creating mature process parameter to produce Special PCB, high Tech precise PCB, 2-32multilayer PCBs, Flexible printed board(FPC) in mass production, as well as PCB assembly sourcing service for our customers in the fied of Aotomatives & Medical, Industril application, Comsumer Electronics etc.

"Quality is the soul of our company". We have full supply chain from base Material(KB, Shenyid) to finished PCB for control quality system, and our factory is equipped with Automated Production Equipments imported from Germany, Taiwan to meet or surpass customers'expectations and specifications. HL-PCB, Your trustworthy of reliable manufacturing PCB to choose and aim to build long standing business cooperationship.

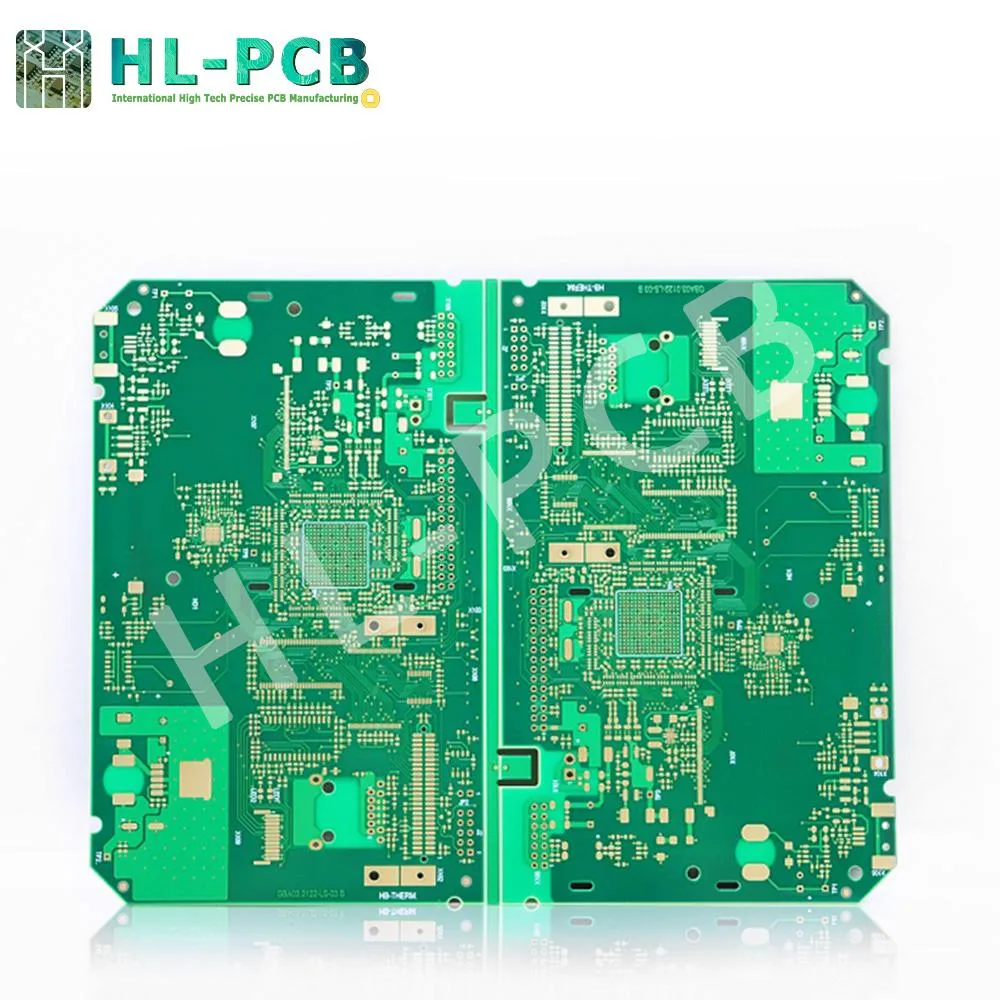

| Products Image: |

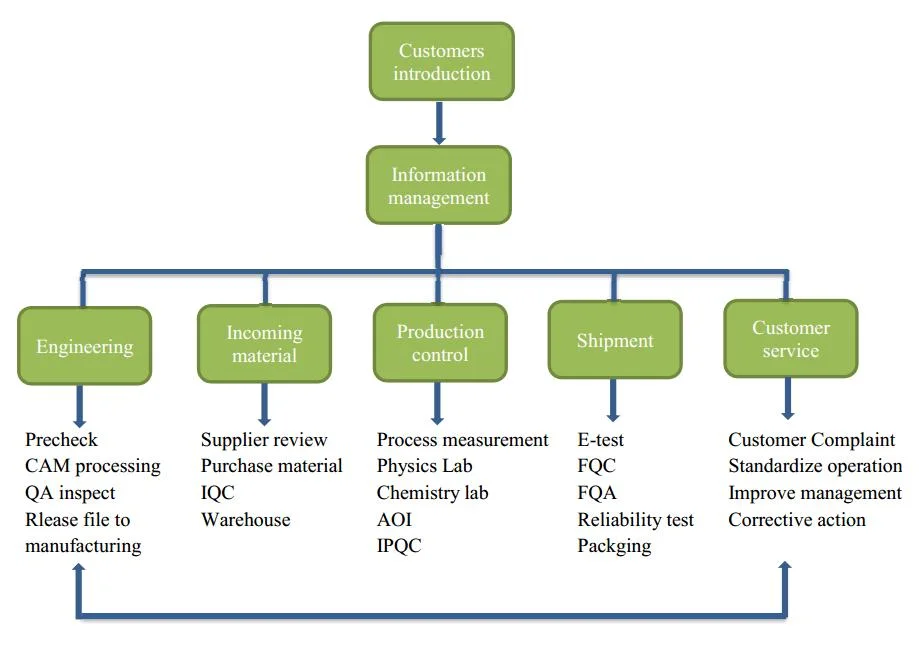

| PCB work flow chart |

| Quality control flow How can we ensure quality ? |

* Raw materials require the starting source from imported brands, to gurranty high quality from the source to eliminate substandard products come out. No matter production process until finished, the PCB boards are tested with special instruments comply with international PCB quality system standard.* All of Gerber file is pre-evaluated strictly before placing order and production, if engineers find out any problem, we will send EQ file with Solutions to check with customer until that is solved. * ERP systemThe whole process of production shortens the delivery time, uses the ERP order management system, implements data monitoring, scientific and rigorous production process, 36processes, provide guarantee for your delivery on time.* Mass production is produced after small batches approved by customer. For further production, we control PCB quality strictly comply to IPC standard system.* All finished PCB will be tested strictly before packing with precise instruments, every process such as AOI test, FQC inspection, FQA final inspection by 100% visual check and equiments test.* Acceptance of 3rd test for finished products before packing, with testing report.

| Process Capacity |

| Process capability and checking parameters | ||

| N0 | ITEM | Technical capabilities |

| 1 | Layers | 2-32 layers |

| 2 | Max.Board Size | 1200mm*625mm |

| 47"*25" | ||

| 3 | Finished Board Thickness | 0.15mm--10.0mm |

| 0.006"--0.4" | ||

| 4 | Finished copper thickness | 35um-420um |

| 1OZ--12OZ | ||

| 5 | Min.Trace Width/Space | 0.075mm/0.075mm |

| 0.003"/0.003" | ||

| 6 | Min.Hole Size | 0.1mm (0.004") |

| 7 | Hole Dim. Tolerance(PTH) | ±0.05mm (±0.002") |

| 8 | Hole Dim.Tolerance(NPTH) | ±0.05mm (±0.002") |

| 9 | Drill Location Tolerance | ±0.05mm (±0.002") |

| 10 | V-Score Degrees | 20DEG-90DEG |

| 11 | Min.V-Score PCB Thickness | 0.4mm(0.016") |

| 12 | N/C Routing Tolerance | ±0.075mm (±0.003") |

| 13 | Min.Blind/Buried Via | 0.1mm (0.04") |

| 14 | Plug Hole Size | 0.2mm--0.6mm |

| 0.008"--0.024" | ||

| 15 | Min.BGA PAD | 0.18mm (0.007") |

| 16 | Materials | FR4,Aluminium,High Tg,Halogen-free,Rogers, ISOLA etc. |

| 17 | Surface Finish | LF-HAL,ENIG,ImAg,ImSn,OSP, Gold plated, ENIG+OSP,HAL+G/F, ENEPIG |

| 18 | Warp & Twist | ≤0.5% |

| 19 | Electrical Testing | 50--300V |

| 20 | Solderability Testing | 245±5ºC,3sec Wetting area least95% |

| 21 | Thermal Cycling Testing | 288±5ºC,10sec,3cycles |

| 22 | Ionic Contamination Testing | Pb,Hg,Cd,Cr(VI),PBB,PBDE are less than 1000ppm |

| 23 | Soldmask Adhesion Testing | 260ºC+/-5, 10S,3times |

| Inspection Equitments |

| Lead time |

| Lead Time | Prototype Sample | Mass Production | ||

| Layers | Quick-turn(hours) | Standard(DAYs) | Quick-turn(hours) | Standard(DAYs) |

| 1. 2L | 24 | 3 - 4 | 3~7 | 8~10 |

| 4L | 48 | 5 - 7 | 7~10 | 12~14 |

| 6.8L | 72 | 7 - 9 | 9~14 | 15~18 |

10L above | Depending on Case details | |||

| Shipping & Delivery |

| Excellent Service & Our Advantage ? |

* Customized Experience over 10+ years* Imported Raw material to make sure quality 100%* Automatic producting equiment line* ERP system It is the orders manangement system to monitor process data, and can check full producing line clearly, make sure boards delivery on time. * Technical expertise team 50% accumulated over 7+ years experience * Green Enviromental protection Rohs, Halogen Free, HAL lead free raw material, Wastewater recycling handling * One to one 15mins response and further techonical support, keep improving customer's satisfaction.* One-stop solutions PCB manufacturing | PCB Assembly | IC & components sourcing* Focus on High reliability, high mutilayer boards, Special process PCBs etc.

We are wholely family, we are a Creative team, contributing for Smart Electronics!

| PCB Frequently Asked Questions(FAQs) |

Q1: What service do you provide?

We have PCB production, PCB Assembly, SMD Stencil making, component purchase.

Q2: Are you a manufacturer?

Yes, we are a PCB factory located in Baoan District, Shenzhen, and doing export business.

Q3: What kinds of PCB file format can you accept for production? Gerber, PROTEL 99SE, PROTEL DXP, CAM350, ODB+(.TGZ)Q4: What are needed for quotation?PCB: Gerber files and technical data are for PCB quotation;PCBA: PCB information and BOM, testing documents; FPC: Gerber files, CAD demension drawing.Q5: How soon can i expect a response for my quotation request ?We will respond your quotation within 24 hours to the quotation requests.Q6: What is the Lead time? (1)Sample:1-2 Layers: 5 to 7working days4-8 Layers: 10 working days(2)Mass production: 15~30days

For any your project, Gerber file, Please feel free to contact us. Thanks !

Prev: PCB Manufactury Printed Circuit Board Factory Electric Meter Board +Carbon Film Printing

Next: PCB Layout and Assembly Customized Design Professional PCB PCBA Assembly Circuit Board Manufacture

Our Contact