Kinco DC Driving Equipment with Break Magnetic Encoder Electric Low Voltage DC Servo System All-in-One, Integrated Servo Motor

Description Schemes Kinco AGV machine automation and Internet of Things control scheme has the characteristics of stabil

Description

Basic Info

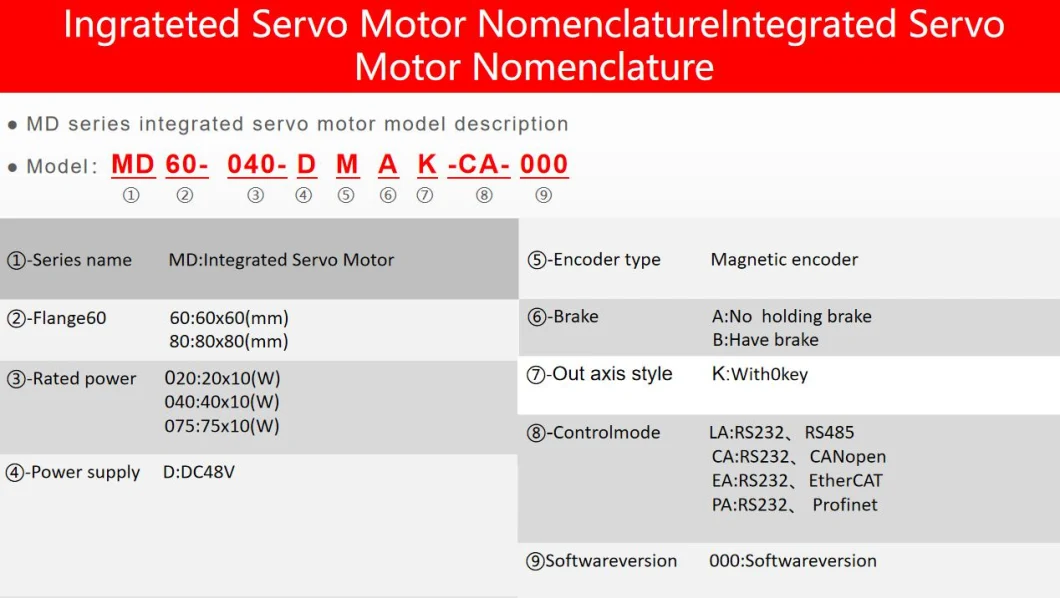

| Model NO. | MD60-075-DMA/BK-LA-000 |

| Servo System | Servo Motor |

| Flange Size | 80mm |

| Rated Power Pn (W) | 750W |

| Rated Torque Tn (Nm) | 2.39 |

| Encoder | Magnetic Encoder |

| Rated Speed Nn(Rpm) | 3000 |

| Input/Output | 4 Inputs 2 Outputs |

| Communciation | RS232/Ethernet |

| Trademark | Kinco |

| Origin | China |

| HS Code | 8501510090 |

| Production Capacity | >100, 000 PCS/Year |

Product Description

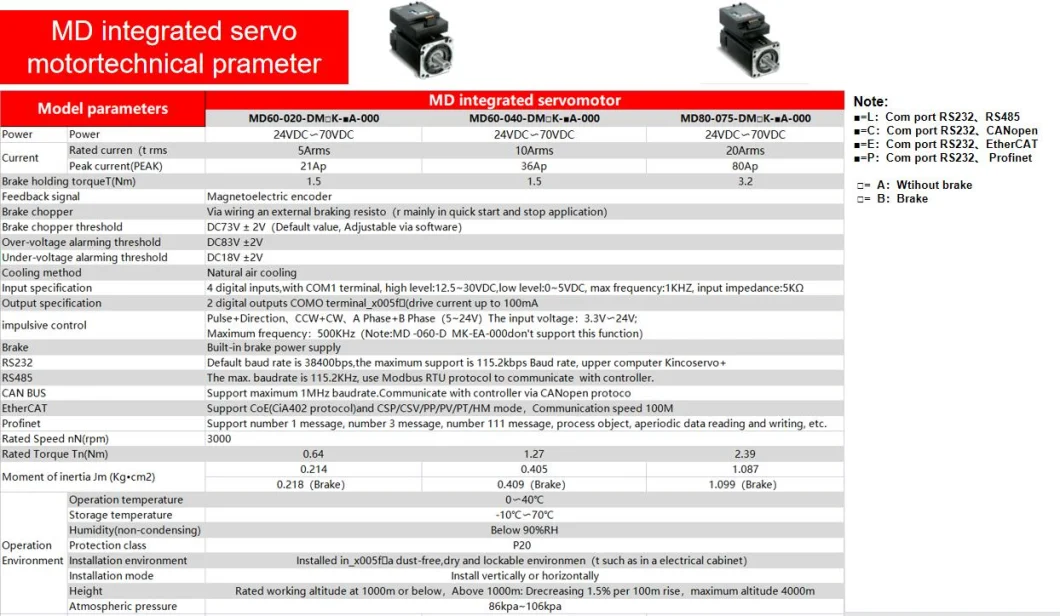

| Model parameters | MD integrated servomotor | |||

| MD60-075-DMAK-LA-000 | MD60-075-DMBK-LA-000 | |||

| Power | Power | 24VDC-70VDC | 24VDC-70VDC | |

| Current | Rated curren(t rms | 20Arms | ||

| Peak current(PEAK) | 80Ap | |||

| Brake holding torqueT(Nm) | 3.2 | |||

| Feedback signal | Magnetoelectric encoder | |||

| Brake chopper | Via wiring an external braking resisto(r mainly in quick start and stop application) | |||

| Brake chopper threshold | DC73V ± 2V(Default value, Adjustable via software) | |||

| Over-voltage alarming threshold | DC83V ±2V | |||

| Under-voltage alarming threshold | DC18V ±2V | |||

| Cooling method | Natural air cooling | |||

| Input specification | 4 digital inputs,with COM1 terminal, high level:12.5~30VDC,low level:0~5VDC, max frequency:1KHZ, input impedance:5KΩ | |||

| Output specification | 2 digital outputs COMO terminal_x005f (drive current up to 100mA | |||

| impulsive control | Pulse+Direction,CCW+CW,A Phase+B Phase(5~24V)The input voltage:3.3V-24V;Maximum frequency:500KHz(Note:MD -060-D MK-EA-000don't support this function) | |||

| Brake | Built-in brake power supply | |||

| RS232 | Default baud rate is 38400bps,the maximum support is 115.2kbps Baud rate, upper computer Kincoservo+ | |||

| RS485 | The max. baudrate is 115.2KHz, use Modbus RTU protocol to communicate with controller. | |||

| Rated Speed nN(rpm) | 3000 | |||

| Rated Torque Tn(Nm) | 2.39 | |||

| Moment of inertia Jm (Kg•cm2) | 1.087 | |||

| 1.099(Brake) | 1.099(Not brake) | |||

| Operation Environment | Operation temperature | 0-40ºC | ||

| Storage temperature | -10ºC-70ºC | |||

| Humidity(non-condensing) | Below 90%RH | |||

| Protection class | P20 | |||

| Installation environment | Installed in_x005f a dust-free,dry and lockable environmen(t such as in a electrical cabinet) | |||

| Installation mode | Install vertically or horizontally | |||

| Height | Rated working altitude at 1000m or below,Above 1000m: Drecreasing 1.5% per 100m rise,maximum altitude 4000m | |||

| Atmospheric pressure | 86kpa~106kpa | |||

Program features and advantages

l. Higher space utilization: the volume of the driver is about 50% smaller than that of the whole machine,which can meet the strict space requirements of AGV;2. Rich communication interface: the driver supports standard CANopen, EtherCAT and other communication modes,which can be seamlessly connected with NDC, Beofuand other mainstream controllers in the market;3. Improve AGV operation efficiency: The overload capacity of the motor is 300% absolute, which can improve the instant overload capacity of the AGV car, and can set

more speed, thus improving the operation efficiency of the car;4. Meet the requirements of heavy-duty and high-precision applications: the motor power segment ranges from 50W to 1.5KW. The encoder supports magnetic coding, Incremental Tamortran type, nikon absolute value, etc.which can help customers develop more comprehensive types such as heavy-duty or high-precision applications;5. Safety and stability: The driver has alarm synchronous braking, 24V brake power output, intelligent energy saving and other functions;

6. Powerful controller: "Tsing Long No. 1" controller integrates magnetic navigation dual drive differential speedsteering wheel control, color-band navigation TWO-DIMENSIONAL code navigation algorithm library, which is more convenient for customers to start the evelopment ,

and the controller interface is rich, integrating 2-way EtherNET, 2-way CAN and 4-way RS485 interface, which is more convenient for customers to control peripheral parts;

7. Connected to the cloud, remote monitoring: The touch screen is internally integrated with 4G or WIF module, which can be directly connected to the cloud platform conveniently and quickly without any additional module.By analyzing and organizing the historical data through the software of Kinco SaaS platform, it can help you find the early fault of the equipment in time, extend the life of the equipment and reduce the operation and maintenance management cost. .Program features and advantages

1. No gear belt, easy insallation and maintenance, simple structure of the car body, savingspace, reducing the weight of the car, reducing energy consumption;2. The roller with 65536 resolution encoder is driven bythe servo electric roller,:whichmakes the upper and lower packages with different weights more accurate and

higher consistent acceleration;3. The car starts at millisecond level and finishes the sta rt instantaneously, with faster response andhi:gher efficiency,:which canada pt tothe loop speed of 3m/s and above;4. Speci ally designed for the roller sorting industry, rated power 400W, rated torque 5Nm,rated speed 700r pm, to meet the vast majority ofthe sorting requirements;5. Support Ethercat, Canopen and Modbus protocol, which can be sea mlessly connected with PLC of Siemens, Beckoff, Omron, etc.,to meet various sorting Communic

ation eds;

6. Support data to go to the cloud,and check the running state of the product and receive ala rm prompt information through the mobile phone in real time. Program features and advantages1. Integrated, modular, compact structure, occupies less equipment space,and can greatly reduce the volume of the electric control cabinet;2. The power line and encoder line are completely eliminated, with convenient wiring and high cost perfor mance;

3. Powerful communication and high real-time integration of CANopen, EtherCAT and other bus communication;

4. Ensure the stable start an stop of the equipment, fast speed and high eficiency, which can guarantee the sorting efficiency of 5,000-600 pieces/hour.. Program features and advantages1. Modular design is more convenient:Inthe AGV scheme of Kinco e-commerce, the drive of two walking wheels is integrated into a two-in-one driver,and the jacking and rotary motors are controlled by an all-i-one machine.The new modular design concept makes THE AGV more convenient in terms of production, assembly and later maintenance.

2. The modular design is more reliable

The modular design ofthe alline machine eliminates the connection betweenthe jacking and rotary motors and the drive, reducing the potential risks such as bad contact and broken wires, and making the AGV system run more reliably.3. Modular design can effectively reduce costs:Save the connection cable between the motor and the driver, effectively reduce the system cost;Modular design makes assembly easier and faster for workers, saves equipment assembly time and reduces labor cost.4. Flexible and diversified scheme configuration:Kinco introduces two dfferent load schemes of 500Kg1000Kg. and customers can freely choose according to different load models

Our Contact

Send now